ʻO ka Nānā Wavelet o ka Overcut In Free-Form Surfaces CNC Machining

Hoʻohana ʻia ka nui o nā pono e like me nā pono mīkini mīkini CNC a me nā kikowaena mīkini i ka hana ʻana i ka pala. Lōʻihi ke kaʻina hana. Hoʻoluhi nā mea hana i ka luhi. I ka manawa e holo ʻole ai, lawe pinepine ʻia i kekona kekona mai ka ʻike kanaka e hana i nā ana e like ai, i hiki ai i ka hopena huahana, ke kumu o nā pohō waiwai nui. Nui a hewahewa nā hōʻike noiʻi kūloko a me nā ʻāina ʻē e pili ana i ka haki pono o nā meahana a me ka ʻike hewa ʻana o ka mīkini ma nā ʻāpana hana maʻamau. Hoʻokumu ka hapa nui o lākou i ka hoʻokuʻu ʻana o ka acoustic, ka ʻoki ʻana a i ʻole ka nānā ʻana i ka haʻalulu, a me nā mea ʻē aʻe, a ua holomua. Eia naʻe, paʻakikī ka hana. Moulds a me nā mea hana ʻē aʻe me nā ʻano pae manuahi ʻole i nele i ka ʻenehana nānā pono. ʻO ke kumu he paʻakikī e ʻike i ka hōʻailona oki loa. ʻO kekahi mea e hāʻawi i nā ala kūpono no ka nānā manawa maoli. Hoʻohana kēia ʻatikala i nā mea hana hana hōʻailona hōʻailona o kēia manawa-ka loiloi wavelet. Hana ʻia ka scanning "kālele ʻia" i nā wā ʻokoʻa a me nā paʻa pinepine o ka hōʻailona kumu e unuhi pono i ka hōʻailona oki loa mai ka manawa pinepine pinepine. 1 Manaʻo Manaʻo Wavelet ʻO ka loiloi Wavelet ka ulu ʻana o ka aniani ʻo Fourier. Hoʻohana ia i kahi Xu Shuxin ma. No nā alapine like ʻole, hoʻololi wale ʻia ka puka aniani manawa ke anamanaʻo ʻia nā ʻano kiʻekiʻe-pinepine e like me ka hoʻonui a me ka hōʻemi ʻana o ka pae unahi a (hoʻemi ʻia) Ke kālailai ʻana a me ka ʻike ʻana i nā ʻano alapine haʻahaʻa (hoʻonui ʻia), Hoʻonui ākea ka puka manawa, a hoʻopili liʻiliʻi ʻia ka puka aniani pinepine, kahi e ʻike ai i ka loli adaptive o ka pukaaniani manawa-pinepine no nā wā like ʻole. Hiki ke hoʻololi i ka hana kumu. E pāheʻe ma ke axis manawa, i hiki ai iā ʻoe ke kālailai i nā kikoʻī o ka hōʻailona ma kēlā me kēia manawa.

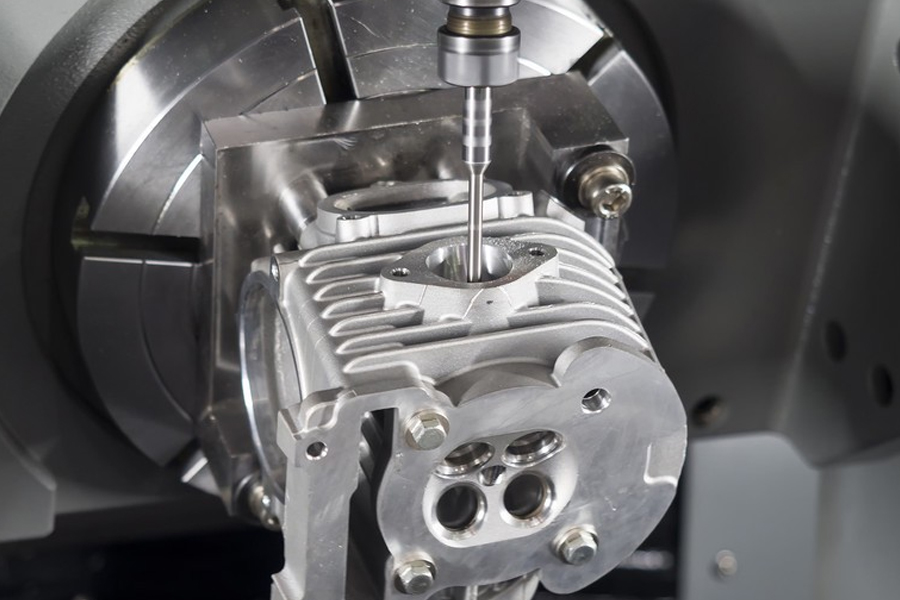

2 Wavelet loiloi loina o ka overcut hōʻailona i ka noa-palapala pae aaioee. I ka mīkini ʻana o CNC, ua kapa ʻia ke kuʻina o ke alo o ka mea hana a me ka ʻili o ka mea hana i ke oki loa ʻana. Pili ia i ka ʻoki kūpono ʻole. Ke hoʻokahuli ʻia ka papa hana manuahi o ka mea hana, hoʻololi koke ka ikaika o ka ʻoki, a laila e loli ana ka mana ʻoki, a ʻo ka motika e hoʻokuke nei i ka mea paʻahana e loli nō hoʻi. No laila, ke nānā nei i ka loli o ka motika me ka ʻokiʻoki hiki ke nānā pololei i ke kūlana mea hana a lawe i ka hōʻailona o kēia manawa mai ka moto manamana. ʻO ke ala maʻalahi loa e hoʻokō i ka I / me ke kūʻē kūʻē. U hoʻohuli, puka ma ke ʻano o ka uila, akā ʻo ka hoʻohui o ke kūpaʻa e hoʻololi i nā ʻano hoʻoili o ka motika ponoʻī, kahi e hoʻēmi ai i ka pololei o ke ana. Hoʻohui ʻia, pono e hoʻololi like ʻia nā mea hana ʻē aʻe i pili i nā wēlau ʻelua o ka resistor e kāpae ai i kona hiki, ka mea kānalua ʻole e hoʻonui i ka paʻakikī o ka ʻōnaehana ana. I ka nānā ʻana i kēia, hoʻohana kēia pepa i kahi mea hoʻonanea ʻume mākenēki Hall i kēia manawa. Pili ka mea ʻike ponoʻī i kahi lako mana DC. Hoʻokumu ʻia kahi māla magnetika i loko o ka ʻaoʻao Hall. Ke hoʻopili ʻia ka pahu hoʻokomo o kēia me kēia i ka mea ʻike, hana ʻia ka mea i kēia manawa ma kāna kikowaena puka. Hoʻokumu ia i kahi māla magnetika kaulike ma loko o ka element Hall. Inā loli ka motika i kēia manawa, e hoʻopili ʻia ka mākau mākia kaulike. I mea e hoʻokō ai i kahi kaulike hou, pono e hoʻololi i ke au e kū nei e like me ia. Ma muli o ka pili o ka mea Hall i kahi pilina laina maikaʻi ma waena o ka hoʻokomo a me ka puka, hiki i ka fluctuation o kāna hōʻailona puka ke hōʻike i ka loli o ka holo o ka motika. E hoʻonoho i kahi hōʻailona puka f (t), a laila hiki ke wehewehe ʻia ka hoʻololi nalu nalu o f (t) e like me ka hoʻokokoke ʻana i ka hoʻonā nui o ka huahana o f (t) a,) (, ka pālākiō e like me ka hana 1, no laila ke kumu o ka hana V / space e kau ʻia I ka hakahaka V / + i, hiki ke hoʻohana ʻia ke kumu orthogonal canonical o ka hakahaka V / + i e hōʻike ai i ka hoʻokokoke ʻana o 1 a me 2'respectively i ka wanaʻao orthogonal o V / + i a me V /. Wahi a ka theorem wanana, ka hoʻonā ʻO ka hōʻailona kikoʻī o 2's e lilo i ke kaʻina orthogonal o ka hōʻailona kumu ma kahi ākea orthogonal o V / e pili ana iā V + 1. E waiho i kēia wahi hui kōkua orthogonal e W /, ʻo ia hoʻi, ke kumu o W / space 2 / (x -2 / n) i loko o ka hakahaka V / + i, no laila ke ʻano o ka orthogonal (5) i hiki ke hoʻohana ʻia ka hakahaka V + 1 e hōʻike ai i ka hōʻailona / (t) GV + 1, a laila hōʻike ke ʻano ma luna e hōʻike ana f (The discrete approximation Af of t) hiki ke kiʻi ʻia mai ka pae kiʻekiʻe discrete kokoke Ad + i / hala kānana. Hiki ke kiʻi ʻia ka hōʻailona kikoʻī D / f o f (t) mai ke kiʻekiʻe kiʻekiʻe kiʻekiʻe loa Ad + i / hala i kahi kānana ʻē aʻe. Hoʻomaopopo ʻia ka kānana h (n) g (n) e ka huahana o loko o ka hana hoʻonui h (t) a me ka hana hawewe ⑴.

No ka hōʻailona kamepiula i laʻana ʻia e ke kamepiula, ʻo ka hōʻailona dyadic ka mea liʻiliʻi. Hana maʻalahi nā mea hana 2 e hana. I mea e hoʻomaʻalahi ai i ke kaʻina hoʻokolohua ʻoiai e noʻonoʻo nei i nā ʻano maʻamau o ka overcutting, ua lawe kēia ʻatikala i ka hoʻokolohua simulate overcut e like me ka mea i hōʻike ʻia. ʻO 1kHz.3.1 ke alapine hōʻike pinepine: no ke ʻano o ka hoʻowalewale ʻana penei: ʻO ke anawaena o ka mea ʻoki mīkini ʻo 8mm, ʻo 1mm ka hohonu o ka ʻoki, ʻo ka wikiwiki o ka spindle n = 500r / min, ka wikiwiki o ka hānai v = 150mm / min, ʻo ka hohonu o ka overcut Hg = 0.05mm, ʻo ka mea hana hana he mea kila A3, a ʻo nā mea hana he kila kiʻekiʻe. ʻO ka hōʻailona ana e like me ka hōʻike ma S i ka hōʻailona ʻoi loa a me ka decomposition wavelet. Hiki ke ʻike ʻia ʻoi aku ka paʻakikī o ka hōʻailona manawa-manawa, a ʻaʻohe hiʻohiʻona i hōʻoki ʻia. ʻO kahi laʻana, ke nānā ʻia i ke kikowaena pinepine, ʻaʻole hiki ke hoʻokō i ka manawa maoli ma muli o ka nele o ka hoʻonohonoho ʻana i ka manawa o ka manawa. ka pahuhopu o. No laila, ua hoʻokau ʻia ka hōʻailona mua i ana ʻia i ka decomposition wavelet, a ua helu ʻia nā hopena hoʻololi i nā hopena hoʻololi. Hiki ke ʻike ʻia mai nā hopena o ka hoʻololi ʻana ke hiki mai ka overcut, ʻaʻole maopopo ka nānā ʻana i ka pālākiō liʻiliʻi (ke alapine kiʻekiʻe), akā akāka ka hiʻohiʻona overcut ma ka pā hāhā. Hōʻike ia i ka nānā maoli ʻana, hiki ke hoʻonohonoho i kahi paepae ma kēia pālākiō e ʻike ai i ka moku ʻoki, a aia ke kiko o kona kaha i nā ʻaoʻao manawa ʻelua i ka pakuhi hoʻololi wavelet, kahi maʻalahi no ka nānā manawa maoli . 3.2 Ke ho'āʻo hoʻokiʻoki ʻelua mau ʻano hōʻike: 10mm ke anawaena o ka mea wili, ʻoki hohonu = 0.5mm, wikiwiki kālī n = 500r / min, wikiwiki wikiwiki hānai = 150mm / min, hohonu hohonu Q1mm, nā mea hana he A ke kai, nā mea pono hana kila kiʻekiʻe wikiwiki Hiki ke ʻike ʻia ka hōʻailona ana a me kāna decomposition wavelet mai ke kiʻi. Hiki ke ʻike ʻia mai ke kiʻi ʻaʻole maopopo ke kiko kikoʻī i ke kiʻekiʻena alapine kiʻekiʻe. Eia nō hoʻi ma ka pā hāhā, ua hōʻike akāka ʻia ka hiʻohiʻona ʻoi loa. 4 Panina Wavelet hoʻololi i loko o ka manawa-pinepine localization o ka hōʻailona Hāʻawi i kahi kumu makemakika, lawe i ka hana loiloi wavelet, hiki ke kālailai i ka hōʻailona mai ka manawa manawa a me ke kikowaena pinepine i ka manawa like, a hoʻokō i ka hoʻonohonoho manawa manawa pinepine o nā helu. o ka hoihoi. I ka mīkini ʻana o NC o ka papa hana manuahi o ka mea hana, ʻo ka overcutting kahi ʻano maʻamau o ka holo pono ʻole. Loaʻa i ka helu komo kahi ʻike ʻike pinepine, akā paʻakikī e loaʻa i ka ʻike pili e pili ana i ka overcutting wale nō mai ka nānā ʻana i ka manawa. Hiki i ka loiloi wavelet ke nānā i ka hōʻailona ma nā manawa a me nā ʻāpana like ʻole, a hiki ke huki pololei i nā ʻike like ʻole e pili ana i ke kiko hoʻololi pinepine. Hōʻike ia i ka manawa, hoʻohana ka hakahaka i ka nānā ʻana i ka "nānā" ʻana e nānā i ka ʻike i kau ʻia. ʻOiai ʻaʻole maopopo ke aniani i kekahi mau pūʻali alapine, i nā pēpē alapine, ʻike maopopo ʻia ka waiwai coefficient wavelet, hiki ke hoʻomaopopo pono i ka mokuʻoki o ka mea hana i ka manawa maoli.

E ʻoluʻolu e mālama i ke kumu a me ka helu wahi o kēia ʻatikala no ka paʻi hou ʻana: ʻO ka Nānā Wavelet o ka Overcut In Free-Form Surfaces CNC Machining

Minghe ʻOihana Casting Die hoʻolaʻa ʻia no ka hana ʻana a hāʻawi i ka maikaʻi a me ka hana kiʻekiʻena hana ʻana i nā ʻāpana (metala make e hoʻolei ana i nā ʻāpana i ka nui Ke kīloi ʻana ʻo Thin-Wall Die,Ka Hapa Hapa Kaʻa Hapa,ʻO ka hoʻoheheʻe ʻana o ke keʻena anu), Ke Kūʻai Wāwae (Die Casting Service,Cnc mīkini,Hana Mould, ʻIlikai Ma luna). Hoʻokipa ʻia nā mea make Alumini maʻamau, magnesium a Zamak / zinc make casting a me nā koi hoʻoiho ʻē aʻe e hoʻokaʻaʻike iā mākou.

Ma lalo o ka hoʻomalu o ISO9001 a me TS 16949, lawelawe ʻia nā kaʻina hana āpau ma o nā haneli he nui o nā mīkini ninini make, nā mīkini 5-axis, a me nā pono hana ʻē aʻe, mai nā blasters a i nā mīkini holoi ʻo Ultra Sonic. kime o nā ʻenekini ʻike, nā mea hana a me nā mea nānā e hana i ka hoʻolālā a ka mea kūʻai aku.

Mea hana aelike o ka hoʻoheheʻe make ʻana. Hiki i nā mākau ke komo i nā ʻāpana alumini anu e hoʻolei ana i nā ʻāpana mai 0.15 lbs. i 6 lbs., hoʻonohonoho wikiwiki i hoʻonohonoho ʻia, a me ka mīkini ʻana. ʻO nā lawelawe i hoʻohui ʻia me ka waiwai nā polishing, vibrating, deburring, shot blasting, pena, plating, coating, Assembly, a me nā meahana. Hana pū nā meahana me nā alloys e like me 360, 380, 383, a me 413.

Kōkua hoʻolālā hoʻolei Zinc make casting / ʻenehana ʻenehana ʻelua. ʻO ka mea hana hana hana maʻamau no ka hoʻoheheʻe ʻana i zinc zinc. ʻO ka hoʻoheheʻe liʻiliʻi ʻana, nā kiʻekiʻena make kiʻekiʻe, nā hoʻoheheʻe hoʻoheheʻe multi-slide, nā hana hoʻoheheʻe maʻamau, kahi make a me nā hana make make kūʻokoʻa a hiki ke hana ʻia nā kīkō i hoʻopaʻa ʻia. Hiki ke hana i ka hoʻoheheʻe ʻana i ka loa a me ka laulā a i ka 24 in. I +/- 0.0005 in. Ke ahonui.

ISO 9001: 2015 mea hana i hōʻoia ʻia o ka magnesium make, hiki i nā mea hiki ke hoʻokomo i ka magnesium make kiʻekiʻe a hiki i 200 ton keena wela & 3000 keena anuanu, hoʻolālā mea hana, hoʻonani ʻana, hoʻoheheʻe ʻana, mīkini, pauma a me ka pena wai, piha QA me nā hiki CMM. , ʻaha kanaka, ʻōpala & hoʻouna.

ITAF16949 i hōʻoia ʻia. Pākuʻi ʻia kahi lawelawe hoʻolei hou hoʻoili waiwai,wailū,Kāpili Gravity, ʻO ka mōkī holo Foam,Ka Kūleʻa Kalima,Huina Kāleka,Holo paʻa punahelu, .Kāpono pū me EDI, kōkua ʻenehana, hoʻohālikelike paʻa a me ka hana lua.

ʻO nā ʻĀpana Casting Nā ʻ Caselelo Nānā Nānā no: Nā Kaʻa, nā Paikikala, nā mokulele, nā mea kani, nā pono wai, nā mea uila, nā mīkini uila, nā mīkini, nā pono uila, nā mea paʻa, nā uaki, nā mīkini, nā ʻenekini, nā lako pono, nā mea kāhiko, nā Jigs, Telecom, kukui Nā Robots, nā kiʻi kālai, nā pono kani, nā pono haʻuki, nā pono hana, nā mea pāʻani a me nā mea hou aʻe.

He aha ka mea e hiki ai iā mākou ke kōkua iā ʻoe e hana aʻe?

∇ E hele i ka pūnaewele no Make Casting Kina

→ʻO nā ʻāpana hoʻolei-E ʻike i nā mea a mākou i hana ai.

→ Nā ʻōlelo aʻoaʻo i hoʻohālikelike ʻia e pili ana Nā lawelawe hoʻolei make

By ʻO Minghe Die Casting Hookah | Māhele: Nā ʻatikala kōkua |Material Nā huaʻōlelo: Hina ʻĀina Alumini, Hoʻolei Zinc, ʻO ka hoʻoheheʻe ʻana o ka makanekiuma, Hina Titanium, He Waimana kila, Hoʻolei Keleawe,Hoʻolei Keleawe,Kiʻi wikiō,Ka moʻolelo o ka moʻolelo,Kāleka Pale Uila | Pau nā manaʻo