Pehea e hoʻomaikaʻi ai i ke ana ʻana o ke ana o ka spheroidization rate

ʻO ka pae spheroidization o ka home maʻamau spheroidal graphite cast iron cast ke koi ʻia e kiʻi i ka pae 4 a i luna paha, (ʻo ia hoʻi, ʻo 70% ka helu spheroidization), ʻo ka nui o ka spheroidization i loaʻa i ka foundry nui ma kahi o 85%. I nā makahiki i hala iho nei, me ka hoʻomohala ʻana i ka hana hao hao nodular, keu hoʻi i nā ʻoihana me nā koina kiʻekiʻe no ka hana ʻana i ka mana makani a me ke ʻano o ka hoʻolei ʻana, koi ʻia ka pae spheroidization e hōʻea i ka pae 2, ʻo ia hoʻi, piʻi ka spheroidization ma mua o 90%. Nānā a hoʻomaikaʻi ka hui a ka mea kākau i ka spheroidization a me ke kaʻina inoculation i hoʻohana ʻia ma QT400-15, a me ka agena spheroidizing a me ka inoculant, no laila ua piʻi ka nui o ka spheroidization o ka nodular cast iron ma mua o 90%.

1. Ke kaʻina hana mua

Iecaianoaaiiuo kaʻina:

- Hāʻawi nā mea hoʻoheheʻe ahi i ka umu ahi waena 2.0T a me ka umu hana ʻoihana 1.5T;

- ʻO ka hoʻohui ʻana o QT400-15 wai hao mea ʻω (C) = 3.75% ~ 3.95%, ω (Si) = 1.4% ~ 1.7%, ω (Mn) ≤0.40%, ω (P) ≤0.07%, ω ( S)) ≤0.035%;

- ʻO ka mea hoʻohana spheroidizing i hoʻohana ʻia i ka mālama spheroidizing ʻo 1.3% a 1.5% RE3Mg8SiFe oka a;

- ʻO ka inoculant i hoʻohana ʻia i ka lapaʻau inoculation ʻo 0.7% ~ 0.9% 75SiFe-C paʻa. Lawe ka lāʻau spheroidizing i nā kuʻi ʻelua a me nā ʻano flushing:

ʻO ka mea mua, hana ʻia he 55% ~ 60% o ka hao, a laila hoʻokō ʻia ka spheroidizing, a laila hoʻohui ʻia ka inoculant, a laila hoʻohui ʻia ke koena o ka wai hao.

Ma muli o ka hana kuʻuna o ka spheroidization a me ka inoculation, ʻo ka helu spheroidization i ʻike ʻia e kahi poloka hōʻike wedge hoʻokahi me ka mānoanoa o 25 mm ma kahi o 80%, ʻo ia hoʻi, ʻo ka pae spheroidization ka 3.

2. Hoʻolālā hoʻolālā e hoʻomaikaʻi i ka helu spheroidization

I mea e hoʻonui ai i ka helu spheroidization, ua hoʻomaikaʻi ʻia ka spheroidization kumu a me ke kaʻina inoculation. ʻO nā hana nui: hoʻonui i ka nui o ka mea spheroidizing a me ka inoculant, ka hoʻomaʻemaʻe hao i hoʻoheheʻe ʻia, a me ka hoʻomaʻemaʻe ʻana i ka desulfurizing. Ke ho'āʻo mau nei ka helu spheroidization me kahi poloka hoʻowali wedge hoʻokahi o 25 mm. Penei ke kumumanaʻo kikoʻī:

- (1) Nānā i ke kumu o ka haʻahaʻa spheroidization rate o ke kaʻina hana mua. Ua manaʻo ʻia ua liʻiliʻi ka nui o ka spheroidizing agents, no laila ua hoʻonui ʻia ka nui o ka spheroidizing agents mai 1.3% a 1.4% a 1.7%, akā ʻaʻole i hoʻokō ka spheroidizing rate i nā koina. . (2) ʻO kekahi kuhi ʻē aʻe ka hopena o ka spheroidization haʻahaʻa e ka hana maikaʻi ʻole a i ʻole ka hōʻemi momona. No laila, ua hoʻonui ka hoʻokolohua i ka mahele inoculation mai 0.7% a i 0.9% a i 1.1%, a ʻaʻole i hoʻokō ka spheroidization rate i nā koina.

- (3) Hoʻomau e kālailai a manaʻo he nui aku nā mea i hoʻohui ʻia i loko o ka hao hoʻoheheʻe ʻia a me nā mea nui o ka spheroidization interruptions paha ke kumu o ka haʻahaʻa spheroidization rate. No laila, lawe ʻia ka hoʻomaʻemaʻe wela kiʻekiʻe o ka hao hoʻoheheʻe ʻia. ʻO ka mahana hoʻomaʻemaʻe wela kiʻekiʻe kaohi ʻia ma 1500 ± 10 ° C, akā ʻaʻole i ʻoi aku ka nui o ka spheroidization 90%.

- (4) ʻO ka nui o ka ω (S) e hoʻopau pono i ka lāʻau spheroidizing a hoʻonui i ka hāʻule o ka spheroidization. No laila, hoʻonui ʻia ka hoʻomaʻemaʻe desulfurization e hoʻoliʻiliʻi i ka wai paʻa wai mua ω (S) mai ka 0.035% a i lalo o ka 0.020%, akā ʻo ka helu spheroidization wale nō i hōʻea i 86%. Hōʻike ʻia nā hopena hōʻike o nā hoʻolālā ʻehā ma luna i ka Papa 1. ʻO ke ʻano a me nā pono mechanical o ka poloka hoʻāʻo e like me ka wedge i kū ʻole i nā koina.

3. ʻO ka hoʻolālā hoʻomaikaʻi hope loa i lawe ʻia

3.1 Nā ana hoʻomaikaʻi kikoʻī

- ʻO nā mea maka he hao puaʻa, palaka a emi iki paha ka pala a me nā mea hana hou;

- Ka hoʻopau ʻana i ka hao hoʻoheheʻe ʻia e ka hoʻohui ʻana i ka lehu soda (Na2CO3) i ka umu ahi;

- E hoʻohana iā Foseco 390 pretreatment konohiki e pre-deoxidize i loko o ka ʻeke;

- Hoʻomaʻamaʻa Spheroidizing me Fozco Nodulizer;

- Ke hoʻohana nei i ka silicon carbide a me ka ferrosilicon i hui pū ʻia me ka inoculation.

ʻO ke kaohi o ka hana hoʻoheheʻe hao o ke kaʻina hana hou: ω (C) = (3.70% ~ 3.90%, ω (Si) = 0.80% ~ 1.20% [hoʻolei ω (Si hope) = 2.60% ~ 3.00%], ω ( Mn) ≤ 0.30%, ω (P) ≤0.05%, ω (S) ≤0.02%. Ke ʻoi aku ka nui o ka hao hoʻoheheʻe ʻia (S) i ka 0.02%, hoʻohana ʻia ka lehu soda no ka desulfurization i mua o ka umu ahi, no ka mea ʻO ka hopena desulfurization kahi hopena endothermic, koi ʻia ka mahana desulfurization e kaohi ʻia ma kahi o 1500 ° C, a ʻo ka nui o ka lehu soda i hoʻohui ʻia ma 1.5% ~ 2.5% e like me ka nui o ω (S) i ka hoʻoheheʻe ʻana i ka umu ahi .

I ka manawa like, lawe ka pūʻulu lapaʻau spheroidizing i kahi pūʻolo lapaʻau ʻano palau. ʻO ka mea mua, e hoʻohui i ka 1.7% o ka Foseco NODALLOY7RE ʻāpana spheroidizing ʻaoʻao i ka ʻaoʻao o ka dam ma lalo o ka pūʻolo, pālahalaha a paʻa, a hoʻohana i ka 0.2% pauka silicon carbide a me 0.3% liʻiliʻi Ua uhi ʻia ka hapa nui 75SiFe me kekahi papa ma hope o kekahi , a ma hope o ka tamping, ua uhi ʻia me ka hao kaomi, a hoʻohui ʻia ka 0.3% Foseke 390 inoculant i ka ʻaoʻao ʻē aʻe o ka ladle hao hoʻoheheʻe ʻia. Ke kāomi ʻana i ka hao, 55% ~ 60% o ka nui o ka hao i hoʻoheheʻe ʻia i hao mua ʻia. Ma hope o ka pau ʻana o ka spheroidizing react, 1.2% 75SiFe-C inoculant i hoʻohui ʻia a waiho ʻia ke koena hoʻoheheʻe ʻia, a ninini ʻia ka slag.

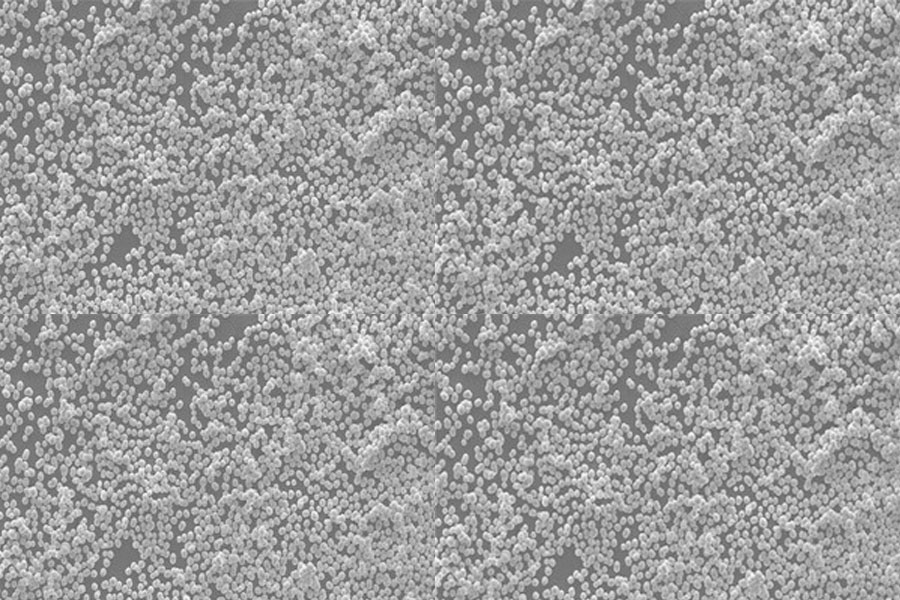

3.2 Nā hopena hōʻike

ʻO ke ʻano o ka hao i hoʻoheheʻe ʻia ma mua a ma hope hoʻi o ka desulfurization, nā pono mechanical a me nā ʻōpala metala o ka 25mm pālua hoʻokolohua kāwili ʻia, a me ke ʻano loiloi o ka helu spheroidization i ke metala metala graphic e ʻike maʻalahi ʻia e ka ʻōnaehana aniani kiʻi metallographic. .

4. Nānā hopena

4.1 Ka mana o nā mea nui i ka helu spheroidization

- C, Si: Hiki iā C ke hāpai i ka graphitization a hoʻoliʻiliʻi i ka likelika o ka waha keʻokeʻo, akā ʻo ka nui o ω (C) e hoʻoliʻiliʻi kiʻekiʻe ai ka CE a maʻalahi e hoʻolele i ka graphite, e kaohi pinepine ʻia ma 3.7% ~ 3.9%. Hiki iā Si ke hoʻoikaika i ka hiki ke kaha kiʻi a hoʻopau i ka sima. Ke hoʻohui ʻia ʻo Si ma ke ʻano he inoculant, hiki iā ia ke hoʻoliʻiliʻi loa i ka mana supercooling o ka hao hoʻoheheʻe. I mea e hoʻomaikaʻi ai i ka hopena inoculation, ua hoʻemi ʻia ka nui o ω (Si) i ka hao hoʻoheheʻe ʻia mai 1.3% a 1.5% a 0.8% i 1.2%, a me ka nui o ω (Si hope) i kāohi ʻia ma 2.60% a i 3.00%.

- Mn: I ke kaʻina hana crystallization, hoʻonui ka Mn i ka hana o ka hao hao i overcool a paipai i ka hoʻokumu ʻana o nā carbides (FeMn) 3C. I ke kaʻina hoʻololi eutectoid, hoʻemi ʻo Mn i ka mahana e hoʻololi i ka eutectoid, stabilize a hoʻomaʻemaʻe i ka pearlite. ʻAʻohe o Mn mana i ka helu spheroidization. Ma muli o ka hopena o nā mea maka, kaohi ω (Mn) <0.30%.

- P: Ke ω (P) <0.05%, paʻa paʻa ia i Fe, a paʻakikī e hana i kahi phutropical eutectic, ka mea i loaʻa iki ka hopena ma ka helu spheroidization o ka hao ductile.

- S: ʻO S kahi mea des desoidoidizing. Hoʻopau ʻo S iā Mg a me RE i ka mea spheroidizing i ka manawa o ka spheroidizing E hoʻi hou ʻo Sulfide slag i ka sulfur ma mua o ka paʻa ʻana o ka hao i hoʻoheheʻe ʻia, e hoʻopau hou ana i nā mea spheroidizing, e wikiwiki ana i ka emi ʻana o ka spheroidization, a e hoʻopili hou ana i ka helu spheroidizing. I mea e loaʻa ai kahi helu spheroidization kiʻekiʻe, pono e hoʻemi ʻia ka nui o ω (S) i ka hao maka ma lalo o 0.02%.

4.2 Ka lapaʻau desulfurization

Ma hope o ka hoʻoheheʻe ʻia o ka uku, lawe i nā laʻana a kālailai i ka haku mele. Ke kiʻekiʻe ka nui o ω (S) ma mua o 0.02%, koi ʻia ka desulfurization.

ʻO ke kumu o ka desulfurization lehu lehu: kau i kahi nui o ka lehu soda i loko o ka ladle, e hoʻohana i ka kahe hoʻoheheʻe hao e holo a hoʻowali, decomposes ka lehu soda i ke kiʻekiʻe wela, ʻo Na2CO3 = Na2O + CO2 ↑: ka Na2O i hana ʻia i ka hao hoʻoheheʻe ʻia Sulfuration a me ka hoʻokumu ʻana o Na2S, (Na2O) + [FeS] = (Na2S) + (FeO).

Hoʻokaʻawale a hoʻonā ʻo Na2CO3 iā CO2, e hoʻonāukiuki ana i ka hao hoʻoheheʻe ʻia, kahi e hāpai i ka hana desulfurization. Maʻalahi ke kahe o ka lehu Soda a lana koke, a pōkole loa ka manawa hopena desulfurization. Ma hope o ka desulfurization, pono e hemo i ka slag i ka manawa, inā ʻaʻole ia e hoʻi i ka sulfur. 4.3 Mālama mua-deoxidation lapaʻau, lapaʻau spheroidization a me ka lapaʻau inoculation Hoʻomaʻamaʻa ʻo Foseke 390 i ka hana o ka lapaʻau pre-deoxidation i loko o ka ʻeke, a ma ka manawa like e hoʻonui ai i ka nui o ka hoʻoulu ʻia ʻana o ka graphite a me ka helu o nā ʻāpana graphite i kēlā me kēia ʻāpana, a hiki pū kekahi e hoʻonui i ka helu o ka absorption o Mg. Hoʻonui maikaʻi i ka hiki ke pale aku i ke kūleʻa a hoʻonui i ka helu spheroidization. Loaʻa i ka inoculant ʻo Fochke ω (Si) = 60% ~ 70%, ω (Ca) = 0.4% ~ 2.0%, ω (Ba) = 7% ~ 11%, a ʻo Ba kahi e hoʻolōʻihi i ka manawa hoʻouluulu kūpono. Koho ʻia ka papa NODALLOY7RE o Fozco Nodulizer, a me kāna ω (Si) = 40% ~ 50%, ω (Mg) = 7.0% ~ 8.0%, ω (RE) = 0.3% ~ 1.0%, ω (Ca) = 1.5 % ~ 2.5%, ω (Al) <1.0%. Ma muli o ka hoʻoheheʻe ʻia o ka hao i hoʻoheheʻe ʻia a me nā hoʻoponopono pre-deoxidation, hoʻemi nui ʻia nā mea e hoʻopau i nā nodulizers i loko o ka hao hoʻoheheʻe ʻia, no laila ua koho ʻia kahi nodulizer me ka hapa haʻahaʻa o ω (RE) e hoʻoliʻiliʻi i ka hōʻino ʻana o ka spheroidal graphite morphology na RE. ; ʻO ka mea nui o ka hana ʻo Mg; Hiki iā Ca lāua ʻo Al ke hana i ka hoʻoikaika ʻana i ka incubation. Ke hoʻohana nei i ka silicon carbide a me ka ferrosilicon i hui pū ʻia me ka inoculation, ʻo ka wahi hoʻoheheʻe o ka silicon carbide ma kahi o 1600 ° C, a hoʻonui ʻia ka nucleus aniani grafite i ka wā paʻa, a hoʻohana ʻia nā mea nui o ka ferrosilicon no ka inoculation, kahi e pale ai i ka spheroidization mai ka iho ʻana.

5 Hoʻopau

I ka hana ʻana o ka ferritic nodular cast iron, ke koi ʻia ka nui o ka spheroidization e piʻi i mua o 90%, hiki ke lawe ʻia nā ana aʻe:

- (1) Koho i nā koina kiʻekiʻe e hōʻemi i nā mea de-spheroidization i ka uku.

- (2) Koho i kahi agena spheroidizing me ka hapa haʻahaʻa o RE (RE) e hōʻemi i ka hopena deteriorating o RE ma ka morphology o ka spheroidal graphite.

- (3) ʻO ka ʻike ω (S) o ka hao hoʻoheheʻe mua ma lalo o 0.020%, hiki ke hōʻemi i ka hoʻohana ʻana o nā nodulizers, ʻo ia hoʻi nā mea nodulized i hoʻopau ʻia e ka lua sulfurization o ka slide sulfide.

- (4) Pre-deoxidize i ka hao hoʻoheheʻe ʻia, e hoʻonui i ka nui o nā spherite graphite i kēlā me kēia ʻāpana, e hoʻonui i ka nui o ka spheroidization, e hoʻomaikaʻi maikaʻi i ka hiki ke pale aku i ke kūleʻa ʻana, a hoʻolōʻihi i ka manawa incubation kūpono.

- (5) E hoʻemi i ka nui o ka ω (Si) i ka hao hoʻoheheʻe ʻia, e hoʻonui i ka nui o ka spheroidizing agents, nā inoculant a me nā ʻākea pretreatment āpau, a hoʻoikaika i ka lapaʻau inoculation.

E ʻoluʻolu e mālama i ke kumu a me ka helu wahi o kēia ʻatikala no ka paʻi hou ʻana: Pehea e hoʻomaikaʻi ai i ke ana ʻana o ke ana o ka spheroidization rate

Minghe ʻOihana Casting Die hoʻolaʻa ʻia no ka hana ʻana a hāʻawi i ka maikaʻi a me ka hana kiʻekiʻena hana ʻana i nā ʻāpana (metala make e hoʻolei ana i nā ʻāpana i ka nui Ke kīloi ʻana ʻo Thin-Wall Die,Ka Hapa Hapa Kaʻa Hapa,ʻO ka hoʻoheheʻe ʻana o ke keʻena anu), Ke Kūʻai Wāwae (Die Casting Service,Cnc mīkini,Hana Mould, ʻIlikai Ma luna). Hoʻokipa ʻia nā mea make Alumini maʻamau, magnesium a Zamak / zinc make casting a me nā koi hoʻoiho ʻē aʻe e hoʻokaʻaʻike iā mākou.

Ma lalo o ka hoʻomalu o ISO9001 a me TS 16949, lawelawe ʻia nā kaʻina hana āpau ma o nā haneli he nui o nā mīkini ninini make, nā mīkini 5-axis, a me nā pono hana ʻē aʻe, mai nā blasters a i nā mīkini holoi ʻo Ultra Sonic. kime o nā ʻenekini ʻike, nā mea hana a me nā mea nānā e hana i ka hoʻolālā a ka mea kūʻai aku.

Mea hana aelike o ka hoʻoheheʻe make ʻana. Hiki i nā mākau ke komo i nā ʻāpana alumini anu e hoʻolei ana i nā ʻāpana mai 0.15 lbs. i 6 lbs., hoʻonohonoho wikiwiki i hoʻonohonoho ʻia, a me ka mīkini ʻana. ʻO nā lawelawe i hoʻohui ʻia me ka waiwai nā polishing, vibrating, deburring, shot blasting, pena, plating, coating, Assembly, a me nā meahana. Hana pū nā meahana me nā alloys e like me 360, 380, 383, a me 413.

Kōkua hoʻolālā hoʻolei Zinc make casting / ʻenehana ʻenehana ʻelua. ʻO ka mea hana hana hana maʻamau no ka hoʻoheheʻe ʻana i zinc zinc. ʻO ka hoʻoheheʻe liʻiliʻi ʻana, nā kiʻekiʻena make kiʻekiʻe, nā hoʻoheheʻe hoʻoheheʻe multi-slide, nā hana hoʻoheheʻe maʻamau, kahi make a me nā hana make make kūʻokoʻa a hiki ke hana ʻia nā kīkō i hoʻopaʻa ʻia. Hiki ke hana i ka hoʻoheheʻe ʻana i ka loa a me ka laulā a i ka 24 in. I +/- 0.0005 in. Ke ahonui.

ISO 9001: 2015 mea hana i hōʻoia ʻia o ka magnesium make, hiki i nā mea hiki ke hoʻokomo i ka magnesium make kiʻekiʻe a hiki i 200 ton keena wela & 3000 keena anuanu, hoʻolālā mea hana, hoʻonani ʻana, hoʻoheheʻe ʻana, mīkini, pauma a me ka pena wai, piha QA me nā hiki CMM. , ʻaha kanaka, ʻōpala & hoʻouna.

ITAF16949 i hōʻoia ʻia. Pākuʻi ʻia kahi lawelawe hoʻolei hou hoʻoili waiwai,wailū,Kāpili Gravity, ʻO ka mōkī holo Foam,Ka Kūleʻa Kalima,Huina Kāleka,Holo paʻa punahelu, .Kāpono pū me EDI, kōkua ʻenehana, hoʻohālikelike paʻa a me ka hana lua.

ʻO nā ʻĀpana Casting Nā ʻ Caselelo Nānā Nānā no: Nā Kaʻa, nā Paikikala, nā mokulele, nā mea kani, nā pono wai, nā mea uila, nā mīkini uila, nā mīkini, nā pono uila, nā mea paʻa, nā uaki, nā mīkini, nā ʻenekini, nā lako pono, nā mea kāhiko, nā Jigs, Telecom, kukui Nā Robots, nā kiʻi kālai, nā pono kani, nā pono haʻuki, nā pono hana, nā mea pāʻani a me nā mea hou aʻe.

He aha ka mea e hiki ai iā mākou ke kōkua iā ʻoe e hana aʻe?

∇ E hele i ka pūnaewele no Make Casting Kina

→ʻO nā ʻāpana hoʻolei-E ʻike i nā mea a mākou i hana ai.

→ Nā ʻōlelo aʻoaʻo i hoʻohālikelike ʻia e pili ana Nā lawelawe hoʻolei make

By ʻO Minghe Die Casting Hookah | Māhele: Nā ʻatikala kōkua |Material Nā huaʻōlelo: Hina ʻĀina Alumini, Hoʻolei Zinc, ʻO ka hoʻoheheʻe ʻana o ka makanekiuma, Hina Titanium, He Waimana kila, Hoʻolei Keleawe,Hoʻolei Keleawe,Kiʻi wikiō,Ka moʻolelo o ka moʻolelo,Kāleka Pale Uila | Pau nā manaʻo